Thought LeadersKlaus Lun, Executive Vice President, Tecan and Chris Mason,

Thought LeadersKlaus Lun, Executive Vice President, Tecan and Chris Mason, Professor, Weill Cornell Medical College

In this interview, we talk about the past, present, and future of automation and digitalization in the laboratory with Dr. Klaus Lun and Dr. Chris Mason.

Could you introduce yourselves and your current roles?

Dr. Klaus Lun: I have been with Tecan for about 10 years, running the Life Sciences business – which is our end-user division. During this time, I have witnessed the evolution of automation in this field, and come to understand what our customers want and need.

Dr. Chris Mason: I am a professor of genetics, physiology, and biophysics at Weill Cornell Medicine, and am involved in large-scale genomics, such as clinical genetics, computational biology and even synthetic cellular genomics.

Can you give a brief history of automation and its current impact on the science and technology industries?

Dr. Klaus Lun: Automation in the lab has been around since people started to perform experiments, and evolved from the requirement to do more of what is currently being done. The first real step in automation in the lab was to amplify current processes so that people could go from conducting one experiment at a time to multiple. I think it is fair to say that drug discovery in the pharmaceutical industry was a major driving force behind this change, since there was a period when millions of compounds were being routinely screened to find new drugs. During that time, a lot of the main lab activities were being automated. Whereas today, automation is more of a tool to enable procedures that probably would have been very challenging to do manually.

Image Credit: ShutterStock/Gorodenkoff

How do you think automation changes the experience of working in the lab?

Dr. Chris Mason: I think when you reach the point of having tens of thousands of samples coming in from around the world, they need to be efficiently tracked and analyzed, and that is where you need some degree of automation. Robots can be used for all kinds of automated tasks, such as cell phenotyping, extraction, library prep, and liquid handling. The tools and instrumentation are getting much better and more scalable, which enhances the working experience, as researchers want to focus on thinking about the science and coming up with new ideas, rather than repeating the same process millions of times.

Could you give an example of that kind of research and what automation has made possible that wasn’t previously?

Dr. Klaus Lun: There is a current trend to develop units that incorporate multiple processes in one instrument, with Tecan being one of many companies working in this way. Single-cell biology is an example of something that automation has made possible, making it easy to manipulate these single cells while extracting DNA or RNA. There are many other great examples of things that would simply not have been possible to do previously because the reaction chambers and the flow path would have been too big.

Recently, one of the biggest influences on industrial productivity and research has been the COVID-19 pandemic. How did changes in working styles during the pandemic affect automation, and did it increase the rate of adoption?

Dr. Chris Mason: The COVID-19 pandemic disrupted almost everything, but it did drive us towards implementing more automation, particularly because we needed extra processing power for the influx of COVID-19 patient samples. We needed a means of tracking viral evolution in various municipalities and places around the world, and this forced us to speed up the implementation of new processes, such as diversifying the kinds of samples which would go on an instrument, particularly for extraction.

Dr. Klaus Lun: After COVID-19 hit, we needed to rethink how we were going to work in the lab since the number of staff present at any one time had decreased from, for example, 20 to two. Increasing automation not only freed people up to focus on their research, rather than getting bogged down with manual tasks, but also enabled remote working during the peak of the pandemic.

Image Credit: ShutterStock/HTWE

What other challenges did you face during the pandemic?

Dr. Chris Mason: The biggest problem was that we could not get access to supplies, such as reagents or tips. While that is resolved now, there were times when we reconfigured the system to come up with novel solutions, such as 3D printing our own plastic tips. After doing that for a while, we realized that, in addition to adopting automation, we could also become completely self-reliant. While this is no longer an issue, it is another factor that came up during the pandemic, and it was interesting to see the responses to the stress of the situation.

Dr. Klaus Lun: To add to that, we noticed that there was a very broad interest in automation, with a lot of people contemplating automation that had not considered it before, increasing its prevalence in a lot of industries.

How is digitalization helping in the lab, and how do you differentiate between automation and digitalization?

Dr. Chris Mason: Ideally, digitalization and automation are one and the same. For example, in automated and tracked systems, barcoded objects are automatically moved and tracked based on their contents, and we have observed this increasingly with 2D matrix tubes. We used our system for control purposes, to track exactly which tube had been moved, at which point, and the volume of fluid it contained. So, it is both automated and tracked, meaning it is very clear what happened to each tube at each step. That became very useful at the start of the pandemic as we started to validate and benchmark new kinds of COVID-19 tests.

Dr. Klaus Lun: On the digitalization side, the most obvious change during the pandemic was that people were interacting and working in a virtual environment and looking for support with their products. This meant that there was a big push to ensure that we could find a way to continue supporting our customers in the field, and being able to do this remotely with new tools that we had started to deploy was one of the key goals. One thing that was discussed in detail was a so-called ‘digital twin’ to program our customers’ systems virtually, maximizing productivity for our users – as well as using it for training and script writing.

Image Credit: ShutterStock/ST.art

How will having these sorts of tools affect regular day-to-day work in the lab, and how will that make things more efficient?

Dr. Chris Mason: In our lab, it is great because it is easy to hand off projects. For example, if someone is halfway through a large batch of samples, you can pinpoint exactly where they are at in the project, meaning that the transition between multiple people working on a big project is almost seamless.

Dr. Klaus Lun: Another important tool is the use of virtual reality to improve training. The first time we talked about this, I immediately went out and bought a set of goggles to get a sense of what all those guys were talking about in the lab. Now we have a full product ready, where our users and service staff can put on these goggles and receive full training on an instrument.

What are some of the main challenges involved in implementing an automated, digitalized approach in the laboratory, and how would you encourage people to overcome them?

Dr. Chris Mason: It really is dependent on the lab. One challenge that we have seen a lot, especially in cities, is finding the space to work. I also think that just integrating the technology with existing laboratory information management systems is a challenge. There are also some cases where there is a lack of infrastructure, which is why we are moving toward the automation and digitization of records. I also think that both the informatics and programming of the robots require skill, and, like any skill, you need to practice and have some templates to work from.

Dr. Klaus Lun: We are building a lot of consumer technologies that are very well received by our customers. I think the most efficient way of interacting lies in the vast library of online and virtual courses – where people sit in front of the instrument, and one of our remote trainers gives step-by-step instructions. With the focus still very much on digitalization and remote working, I think we are now in an incredible position where everybody has the tools at hand. I could even log in to Chris’s liquid handling system and help him solve a problem.

Image Credit: ShutterStock/Fotomay

We learnt a lot from COVID-19, including that the impact of other pandemics could be huge. Could you talk a little bit about what biobanking is, why it is important, and how automation is being used in the ongoing process of building up biobanks?

Dr. Chris Mason: We have a new biobank at Weill Cornell, the Aerospace Medicine Biobank, where all astronauts – before, during, and after space flight – have samples taken and banked. We then process some of them using single-cell, immunological, epitope typing, or other genetic assays to determine molecular changes in response to space flight. The rest are aliquoted, banked, and put into storage, sometimes in liquid nitrogen at temperatures of around minus 80 degrees.

A biobank gives you a way to go back in time and use newer methods to replicate past experiments or share samples with people. If someone else has an idea or wants to replicate a clinical result, a biobank gives you a chance to share. More data means more power, and the more bank samples you have, the more you can validate any result again, whether it is a clinical trial or astronaut biology. There are only around 600 people that have ever been to space, and this makes every sample extremely precious because we know very little about the response of the body to space flight, and how we prepare to go to Mars depends on these samples to some degree.

Dr. Klaus Lun: Biobanking is an area that is perfectly suited to automation due to the number of samples involved in most biobanks. The scale of it requires quite a significant IT infrastructure to make sure that you can trace each sample and track what has happened to it. For COVID-19, we saw a significant uptake in database building for patient samples because we were in the early stages of understanding this disease and the different phenotypes that we see across a large population, and biobanking is the first step that labs should take.

Image Credit: ShutterStock/Microgen

What do you expect to see from labs in the future, and how important do you think automation is going to be?

Dr. Klaus Lun: I think that it will replace manual processes that we normally do in the lab and will move towards being an automated infrastructure. Automating small, tedious tasks will free up researchers to focus on scientific progress, using the robotic infrastructure to perform the experiments. From an automation point of view, the pandemic has established one of the biggest shifts in mindset that we have ever seen, and, with that understanding, the life sciences lab of the future will be an incredible and exciting place to be.

Dr. Chris Mason: Even though it sounds futuristic to have robots assisting robots, that is what already happens in manufacturing for automobiles, large boats, and even spacecraft. I think more automation will also be used in library prep, and we will see almost everything automated, from the cellular specimen and tissue preparation, right through to the end of the experiment.

Looking forwards, do you think there are any other imminent drivers of change in the same way COVID-19 was, such as space exploration or the colonization of Mars?

Dr. Chris Mason: I think it will be more multi-omic. Looking at DNA, RNA, proteins, and metabolites from the same cells, you’ll see more metrics being measured during extraction and beyond. I think the future will lead to increased quantification and will be a great time to be a scientist. You could argue that today is already the best time to be a scientist, but I think it will just continue to get better if all goes according to plan.

Dr. Klaus Lun: It’s the century of biology.

About Dr. Klaus Lun

Dr. Klaus Lun is Executive Vice President and Head of the Life Sciences Business division at Tecan. Klaus joined the company in June 2013 as EVP Corporate Development and a member of the Management Board of the Tecan Group. In February 2017, he took over the role as EVP, leading Tecan’s entire end-user business division. Klaus studied biology at the University of Bayreuth and Tübingen, and gained his doctorate in neurobiology at the University of Heidelberg and an MBA in Business Administration from the University of Mannheim.

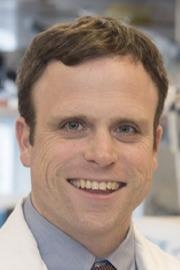

About Dr. Chris Mason

Dr. Chris Mason is a professor of genomics, physiology, and biophysics at Weill Cornell Medicine. Chris is also one of the founding Directors of the WorldQuant Initiative for Quantitative Prediction and co-founder of four biotechnology startup companies. He completed his dual BS in genetics and biochemistry from the University of Wisconsin–Madison, followed by a PhD in genetics from Yale University.

About Tecan

Tecan is a leading global provider of automated laboratory instruments and solutions. Their systems and components help people working in clinical diagnostics, basic and translational research and drug discovery bring their science to life.

In particular, they develop, produce, market and support automated workflow solutions that empower laboratories to achieve more. Their Cavro branded instrument components are chosen by leading instrumentation suppliers across multiple disciplines.

They work side by side with a range of clients, including diagnostic laboratories, pharmaceutical and biotechnology companies and university research centers. Their expertise extends to developing and manufacturing OEM instruments and components, marketed by their partner companies. Whatever the project – large or small, simple or complex – helping their clients to achieve their goals comes first.

They hold a leading position in all the sectors they work in and have changed the way things are done in research and development labs around the world. In diagnostics, for instance, they have raised the bar when it comes to the reproducibility and throughput of testing.

In under four decades Tecan has grown from a Swiss family business to a brand that is well established on the global stage of life sciences. From pioneering days on a farm to the leading role our business assumes today – empowering research, diagnostics and many applied markets around the world

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.